What is unique about 3D printing?

by: Anthony Garland

Follow @AnthonyPGarland

I’ve read many articles that describe why 3D printing is a ‘game changer’, but I have never been satisfied with them. I feel like they over emphasize one thing or leave out other significant advantages. So, I’m writing a series of posts about why 3D printing is unique and the implications.

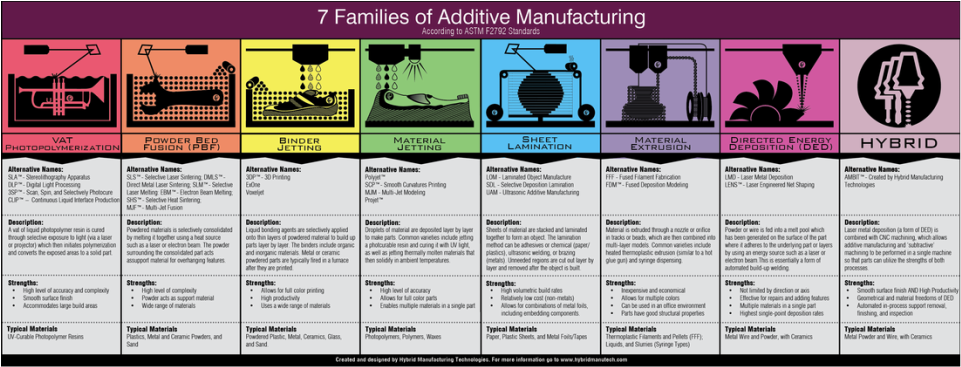

First, what is 3D printing? 3D printing is sometimes called rapid prototyping or additive manufacturing. Technically, 3D printing is a particular type of additive manufacturing (material jetting), so I will use the term additive manufacturing. Additive manufacturing refers to the process of adding material layer by layer to an object to create the whole object (this is in contrast to subtractive manufacturing where the material is removed (like cutting and drilling a piece of wood)). There are seven general categories of additive manufacturing techniques. Hybrid Manufacturing Technologies does a good job describing the different categories in the following picture.

Click on the image for a higher resolution version.

There are three main advantages of additive manufacturing.

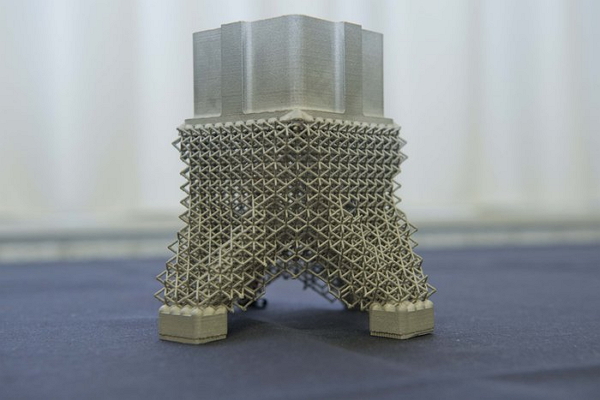

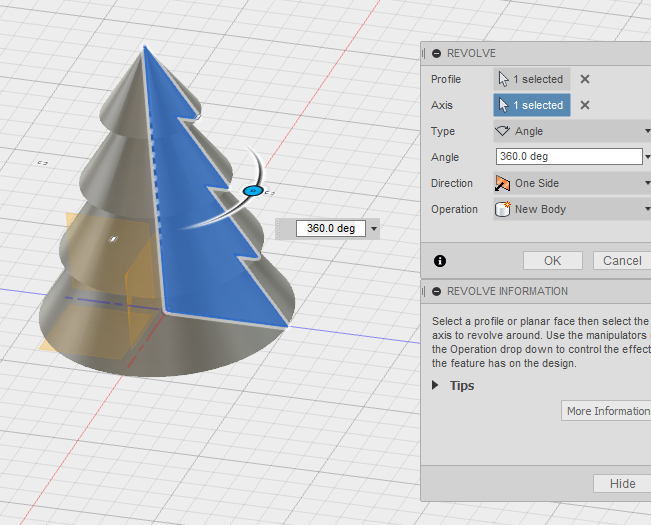

- Increased part complexity does not increase manufacturing cost or time. To help explain the concepts, I'm going to use a food/cooking analogy. If you make a tripe layer chocolate cake it will take significantly more effort and time to make/bake than instant pudding. The principle is: complex things are harder to make (manufacture or cook) than simple things. Additive manufacturing removes this barrier. Complex shapes take the same amount of time and effort to make as simple shapes. The triple layer chocolate cake now takes the same amount of time and effort to make as the instant pudding. So, then the question is, what shape should we make? We should choose shapes which fit our purpose and best meet our needs. In the past we needed to carefully consider the difficulty in manufacturing a part, but this barrier is removed. We can now choose intricate designs, like triple layer chocolate cake, because it is tastier than instant pudding, but we don’t need to worry about spending hours making the cake any more. Finding these optimal shapes can be challenging and is an area of continued research effort. This satellite bracket from the ESA is a good example of a very complex geometry that can only realistically be made using additive manufacturing.

- Multiple materials can be deposited simultaneously or sequentially. Adding multiple materials to a product concurrently is much different than how you normally make things. Consider making the triple layer chocolate cake again. You make the three different bread 'cake' parts in the oven; you make the icing, then you put it all together. Additive manufacturing turns this on its head. You can 'print' the icing and cake all together at the same time. This ability allows you to make fascinating designs where the icing is weaved into the cake, and the cake is weaved into the icing. You can even have secret pockets of icing on the inside where no-one thought you could place icing. So, the question becomes, where should we place each material in a single part? This bread with a 'C' inside is an example of food additive manufacturing with two materials to create unique designs.

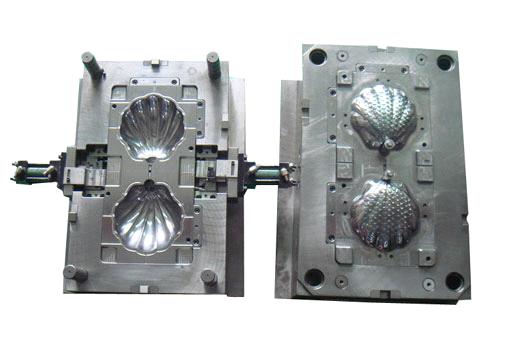

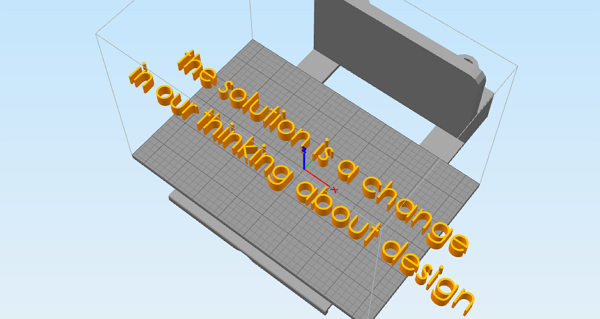

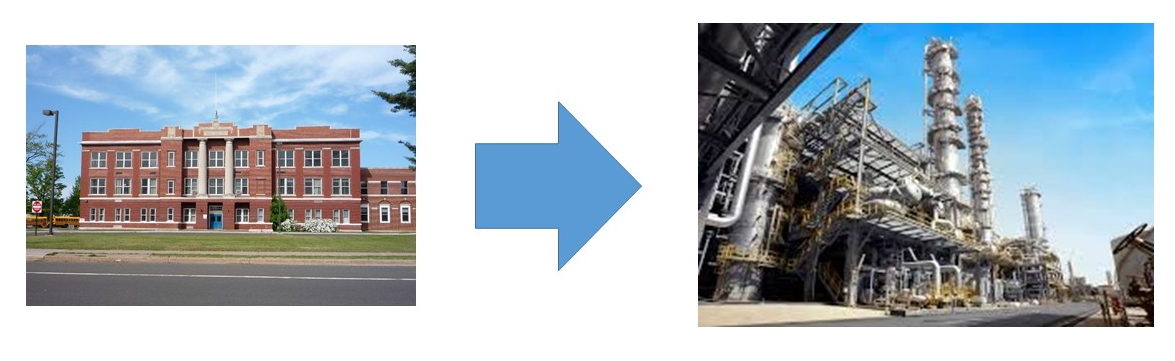

- Minimal manufacturing preparation time. Image if you want to make your triple layer chocolate cake for your friend, and you want to make the cake’s shape with the initials of your friend using the font ‘comic sans’. Unfortunately for you, Walmart does not stock cake pans in the letter shapes, and especially in letter shapes that use the font ‘comic sans’. So, you go to a local machine shop and ask them to make you three cake pans corresponding to the three initials of your friend. They make the pans out of aluminum and change you $1000, and the process takes three weeks. Unfortunately, after three weeks, your friend’s birthday has already passed, so your friendship is now ruined. This type of situation is actually common in engineering where making a mold for a part is typically done in China and takes weeks or months. If you find a mistake in your design and you need to change something, then it will require even more money and time while you wait for your mold to be remade. In contrast, additive manufacturing has minimal preparation time (ie, no mold needs to be made). Additive manufacturing allows you to print the three cakes in the exact shape of each letter in the font ‘comic sans’ within hours. The advantage is huge! Instead of taking weeks to prepare for manufacturing, custom parts can be made in hours. This speedup allows engineers to create prototypes and experiment with new designs quickly. In addition, you can customize designs for each person. Back to the cake analogy, you can make cakes in any font you want for any letter of the alphabet very easily. Below is image of a typical mold required for traditional manufacturing.

So is additive manufacturing a 'game changer'? Absolutely! However, many barriers still need to be over come. Technical challenges still need to be solved. Our thinking about how we design objects needs to change from mass manufacturing to developing a process which allows for mass customization.

Is 3D printing or additive manufacturing overhyped? Yes and No.

Yes, in that the benefits proposed by of additive manufacturing ten years ago are still not here. The overhype was in the speed of solving the technical issues related to additive manufacturing. The magnitude of the size of the problems was underestimated.

No, in that the benefits of additive manufacturing are realistic, but they just aren't here yet. The field of additive manufacturing is evolving rapidly, and the benefits will come eventually.

Join our free mailing list!

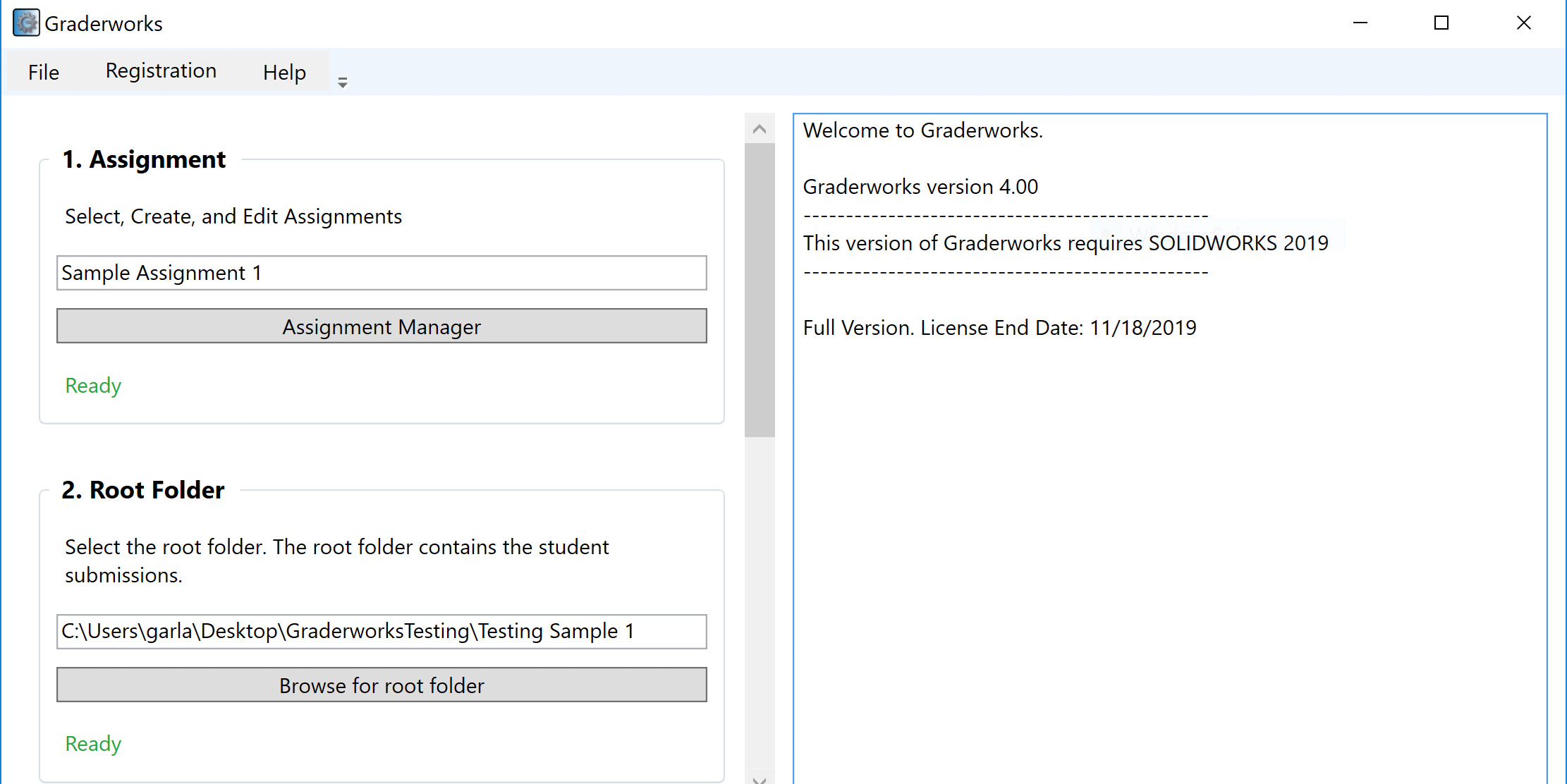

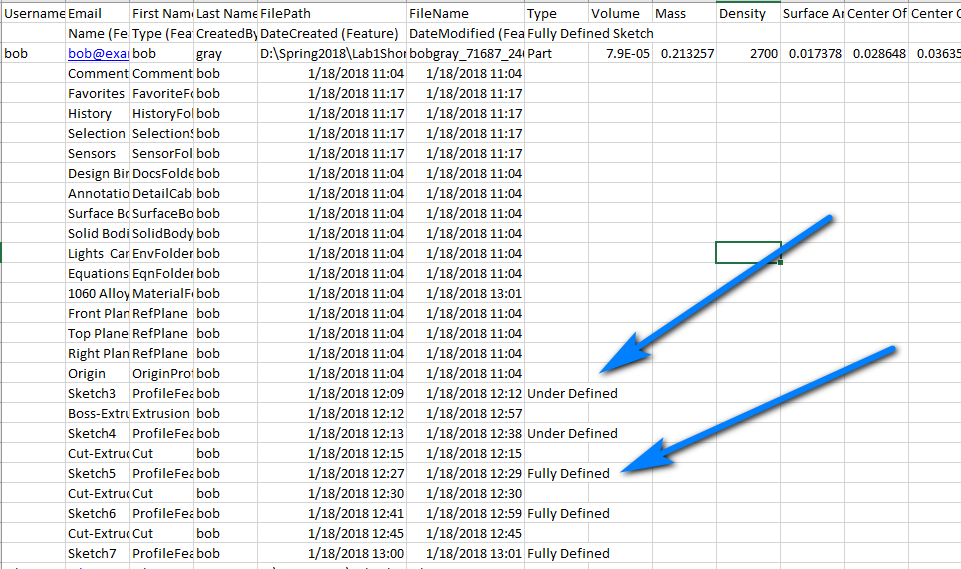

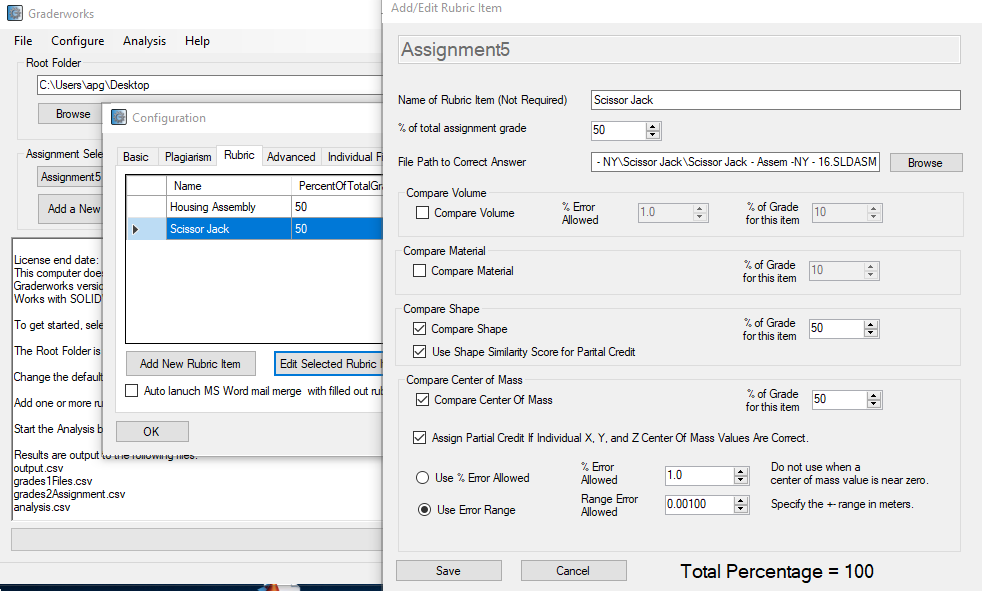

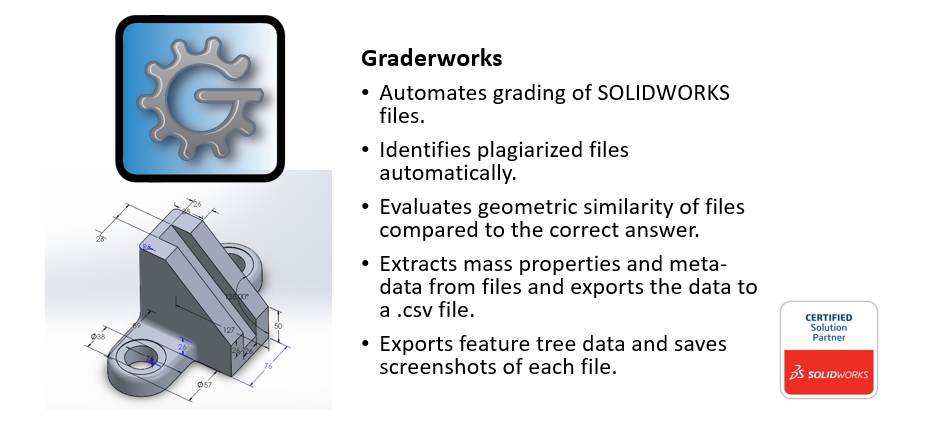

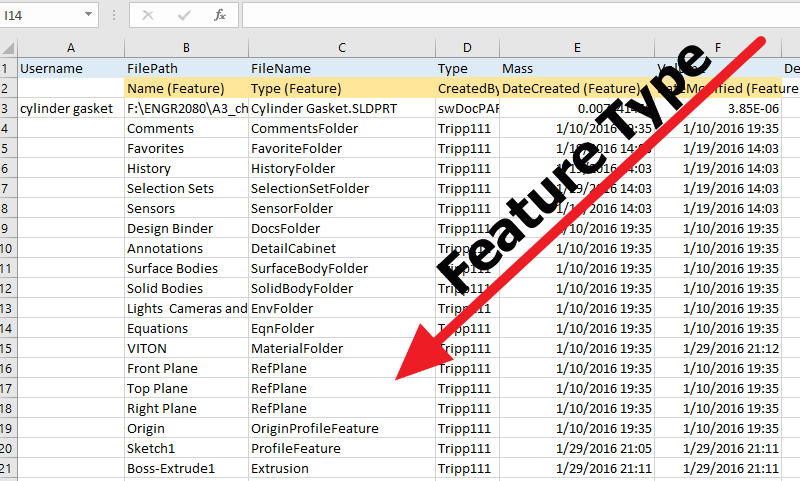

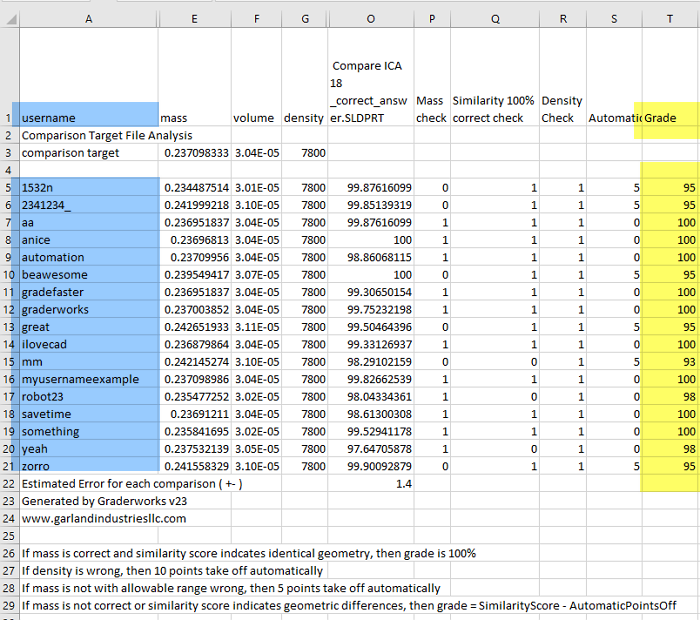

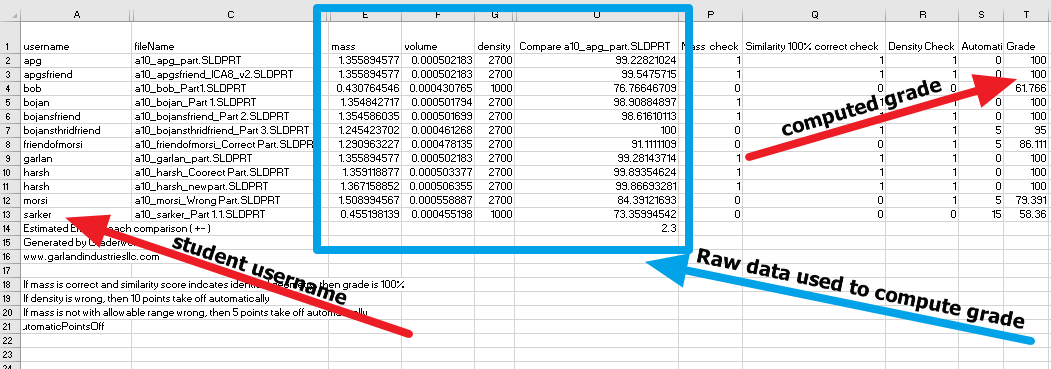

Graderworks

- Grade student's SOLIDWORKS files quickly

- Catch Plagiarism

- Export SOLIDWORKS files to another format in bulk

Recent Articles

Evaluation of Humans and Software for Grading in an Engineering 3D CAD Course

Anthony Garland and Sarah Grigg published a paper showing the effectiveness of a

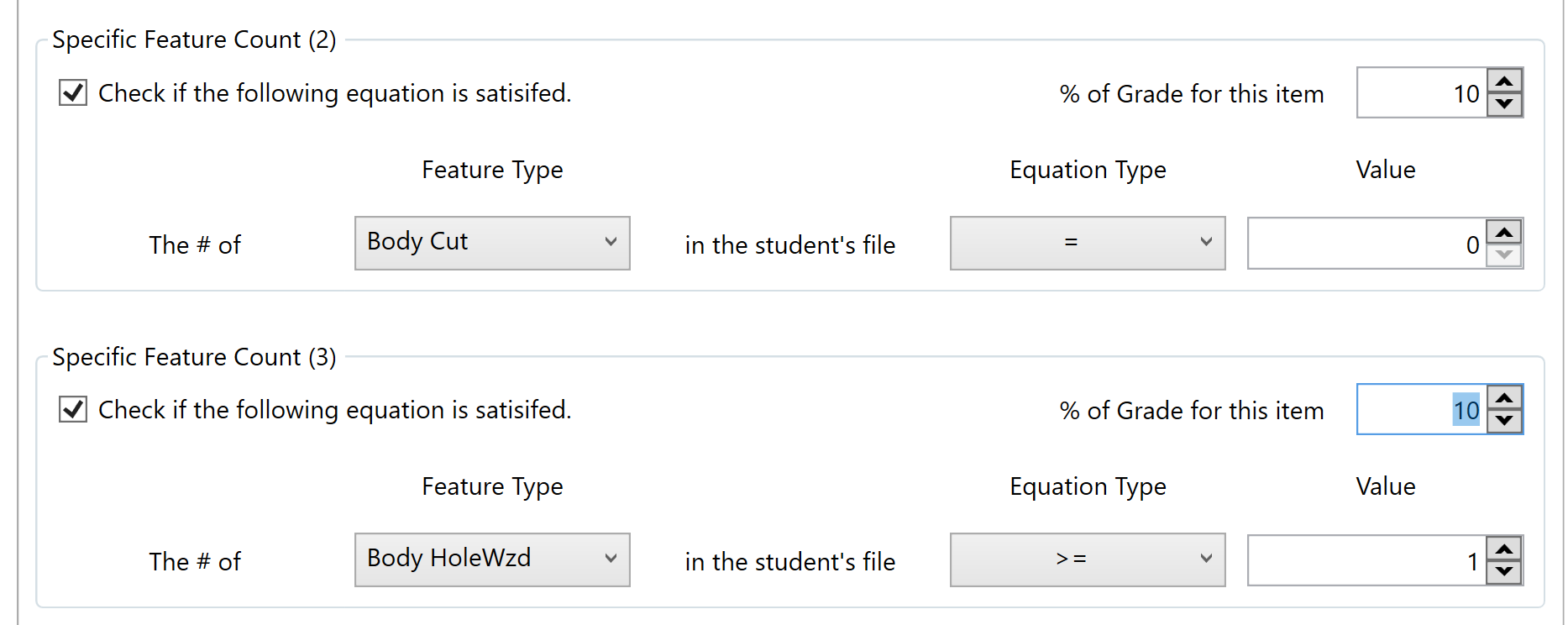

New Grading Items in GW 4.07 - 4.30

Gradeworks can help you automated SOLIDWORKS grading. New grading items include:

Graderworks 3.10 Check for Fully Defined Sketches

What's new in Graderworks 3.10? Increased data collection speed. Check for fully

Graderworks: SW 2017, Config files, Command line args

Graderworks 2.36 and higher is compatible with SOLIDWORKS 2017. Graderworks now

Graderworks: An Official SOLIDWORKS Solution Partner

Garland Industries is happy to announce that Graderworks is now an official SOL

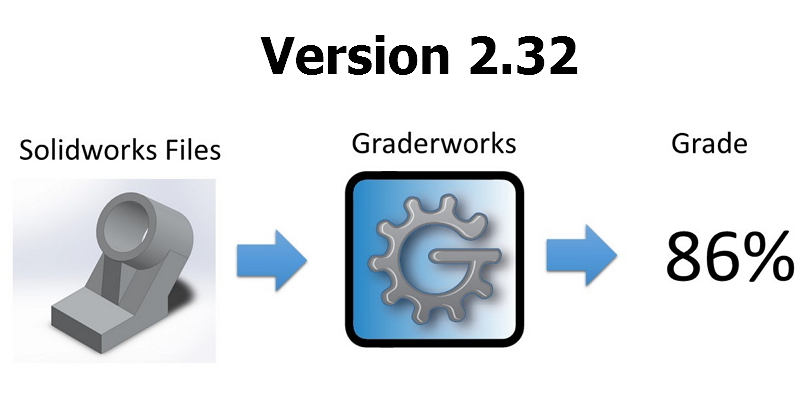

Graderworks 2.32 Release

Graderworks 2.32 represents continued incremental improvement in the overall qua

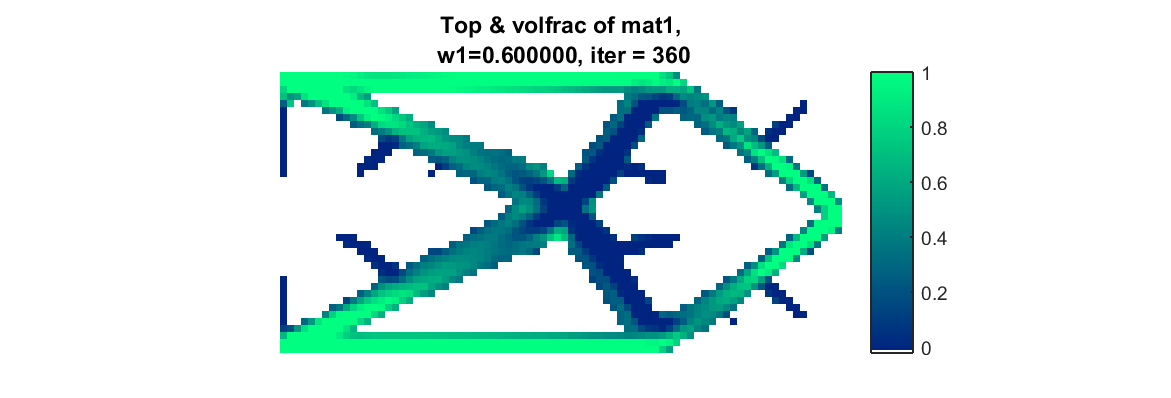

Design Automation Example

A design automation example is given showing topology optimization coupled with

Graderworks 2.3 Release

Graderworks 2.3 allows you to compare the geometric similarity of .stl files wit

Turnitin vs. Graderworks

Graderworks is the Turnitin of 3D models. Not using a plagiarism checker in a So

Getting Started with Graderworks

This tutorial shows how to get started analyzing and grading Solidworks part fil

The Making of Graderworks Video

As an engineering entrepreneur, marketing is not my strength. To make high-quali

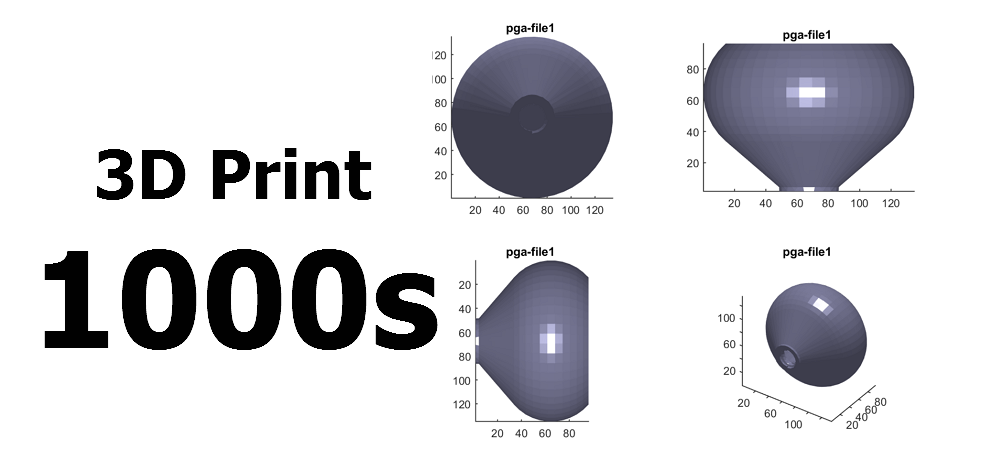

Organizing hundreds of .stl files for 3D printing

How would you 3D print hundreds of .stl files in the shortest time possible usin

What is unique about 3D printing?

3D Printing offers many new exciting possibilities, but why is it unique? Three

How 3D printing works

3D Printing requires three steps. 1. Getting a 3D model. 2. Slicing the model to

Preprocessing files for Graderworks: Converting .rar to .zip

Solidworks students submit .rar files instead of .zip. Graderworks requires .zip

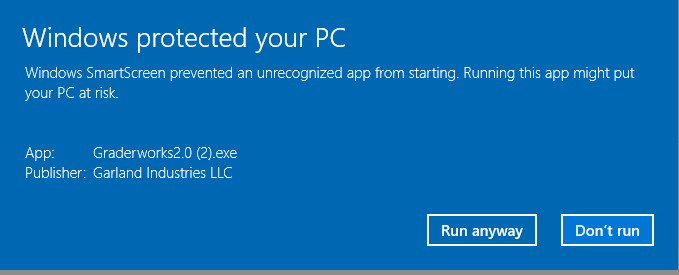

Windows Smart Screen and Code Signing

A short tutorial on how to sign a Windows installer and what the smart screen fi

What should we 3D print?

3D Printing opens the possibility of mass customization of consumer products. Ma

Software, dying on the journey from academic project to commercial tool.

Does software make it from academic research to useful commercial tools? Ignoran