What should we 3D print?

by: Anthony Garland

Follow @AnthonyPGarland

3D Printing is awesome, but if you have just bought a new consumer 3D printer, then likely you have run into a few challenges. These challenges include:

- Finding somewhere to put the 3D printer. The 3D printer will require desk space and a stable environment with a constant temperature and humidity. Also, you probably will want good air circulation (especially if you are printing with ABS).

- Selecting a material to use in your printer. New 3D printers can print using a variety of materials which opens the door for new exciting innovations, but how will you select the right material for the right application?

- Downloading, installing, and running a slicer software to convert 3D models into machine instructions for your printer. Installing a 'slicer' is not hard, but it does require some basic computer knowledge.

- A 3D printer requires a little more maintenance than a 2D printer (I know plenty of people who curse at the office 2D printer because they can't figure out how to make it work.)

- You need a 3D model to print. Where are you going to get a 3D model? This question is surprisingly complex, and opens the door for new thinking about "what is a design?"

"Where are you going to get a 3D model?"

With a 2D printer, you can print stuff from documents and web pages. It is pretty straightforward since it is not a conceptual leap to imagine that what I see on my 2D screen can be printed on a 2D piece of paper. In writing, everything that I need to express my intent can be achieved through letters and words that we have been taught since kindergarten. However, with a 3D model it is much different. Although most of us can read and write well, generating a 3D model is not nearly as simple. Further, the types of models that can be reasonably printed with your desktop printer are limiting. So the question of "what will you print" is constrained in many ways to the abilities of the printer and our ability to generate a 3D model. There are several options for getting a model:

- Download a model off of an online website like Thingiverse. This method is very helpful, but it has limitations. The main limitation is that in spite of having millions of parts, the exact object that you need is probably not on Thingiverse.

- Pay someone to model the part for you. This idea sounds nice and can be done relatively inexpensively. I've hired people on Upwork to draw models for me; however, a major issue is communication. 3D models contain a lot of information, and trying to communicate the needed information to your designer in a non-engineering way will be difficult. "Draw a cylinder that is about 4 inches long with a tube sticking out on the right side about 2/3 of the way up. and make the tube curved so it can fit underneath, . . ." The common language doesn't communicate engineering information very easily which is why engineers use 3D models and technical language.

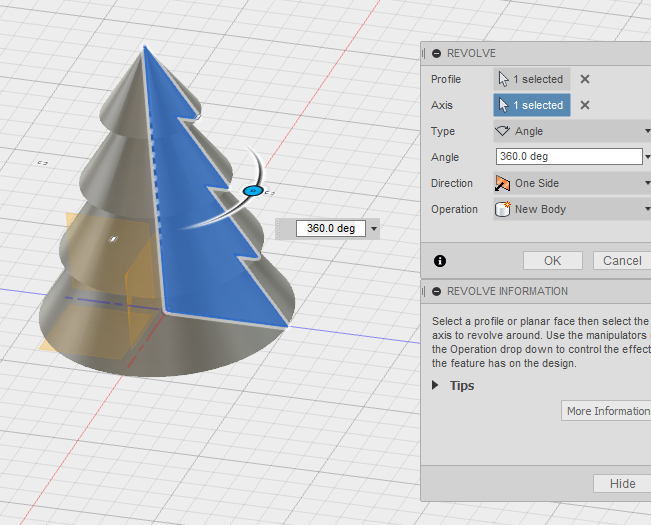

- Learn a CAD program and make the model yourself. This learning is great, but the issue is that CAD programs are expensive and complicated. The reason for the expense and complication is that describing a 3D model is complicated. For example, I teach SOLIDWORKS at Clemson University, and each semester I have about 100 students. It takes the students an entire semester and hours of practice on homework and projects to learn the basics of 3D modeling. SOLIDWORKS is expensive, but other CAD applications are more reasonably priced without all the advanced features of SOLIDWORKS. For example Autodesk Fusion 360 is free for students, educators, hobbyist, and startups.

- Scan something. Scanning objects is great, but the issues are: 1). What size is the object? 2.) What resolution is needed? and 3.) What is the quality of the scanner? Most scanners that are cheap enough for consumers can only scan objects that are the size of a football; however most people would prefer to scan something large (like part of a car). To buy a scanner that can scan large things at a high resolution is going to cost a significant amount of money. Also, the scans are often only a surface or just part of a 3D model (they are not a manifold) which means that the operator will need to manipulate the data further using another program (like meshmixer).

What should we print?

So, if getting a model is so hard, then what is the solution?

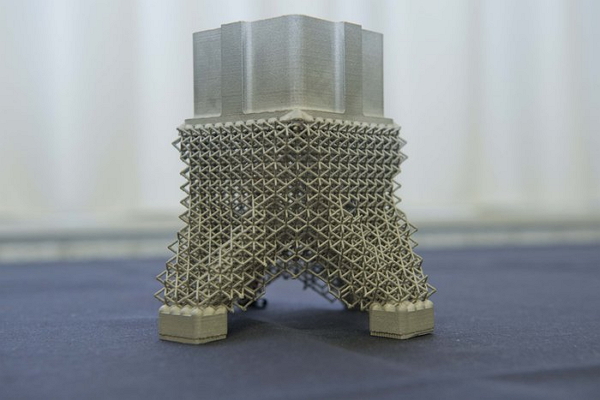

First, 3D printing or additive manufacturing is an engineering tool which helps with prototyping. If you are an engineer with any experience in 3D CAD, you can probably learn an inexpensive CAD software package relatively quickly and make your 3D models. Printing prototypes and functional parts for very specific engineering applications will always be a significant role of 3D printing.

Second, the solution is a change in our thinking about design. One of the three top advantages of additive manufacturing is minimal manufacturing preparation time (read about it here). If manufacturing a new model will cost me the same amount of time and money as making a duplicate of an existing design, then making unique parts will not increase my manufacturing cost. This advantage leads to mass customization of products for consumers, and this mass customization begs the question, 'how will we get the customized designs?' The answer is through design automation.

We need to stop thinking of designs as something we download off of Thingiverse or scan with our 3D scanner, but instead as a carefully crafted automated process which takes inputs and generates 3D models automatically. 3D Designs will be defined by a process rather than geometry. MakerBot's decision to integrate openscad customization tools into the Thingiverse repository is an example of the beginning of this shift. In the future, we will not download a Nike shoe design off of Amazon and have it 3D printed on our home printer. Instead, we will scan our feet, scan our old shoes, upload our data from our fitbits to a Nike server, tell Nike what general style we want, and then Nike's algorithms will generate a new shoe design specially customized just for each of us. Finally, Nike will print our new shoes on their high-tech 3D printers, and the shoes will be delivered by an Amazon drone the very next day.

Join our free mailing list!

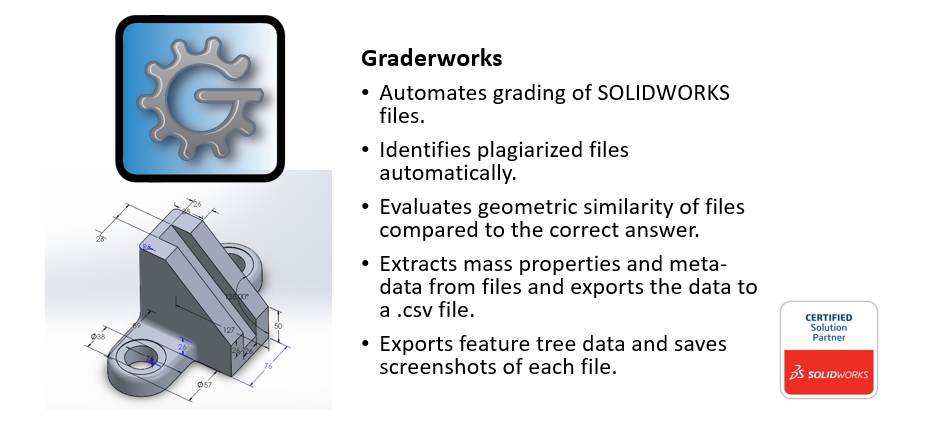

Graderworks

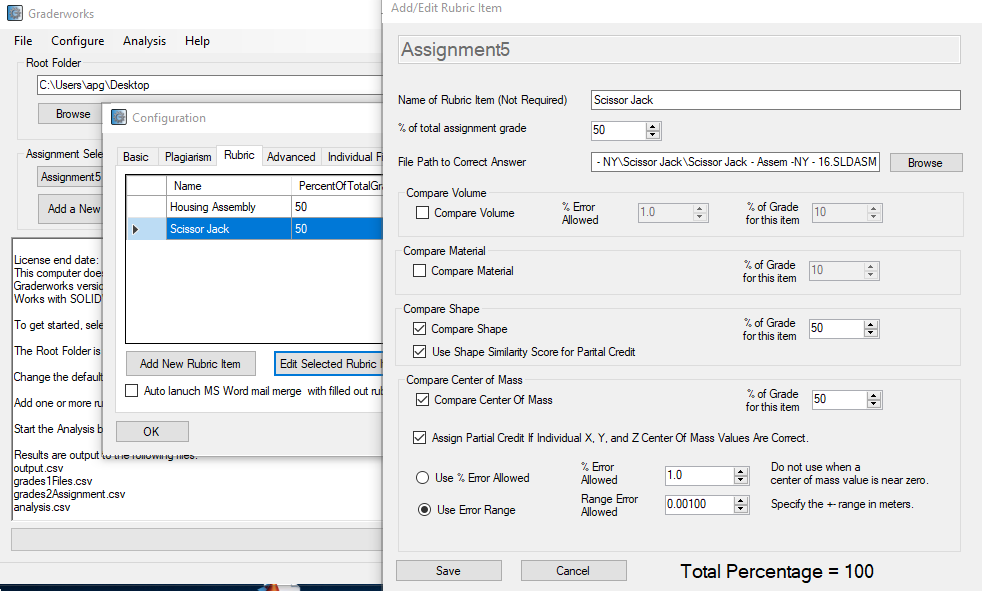

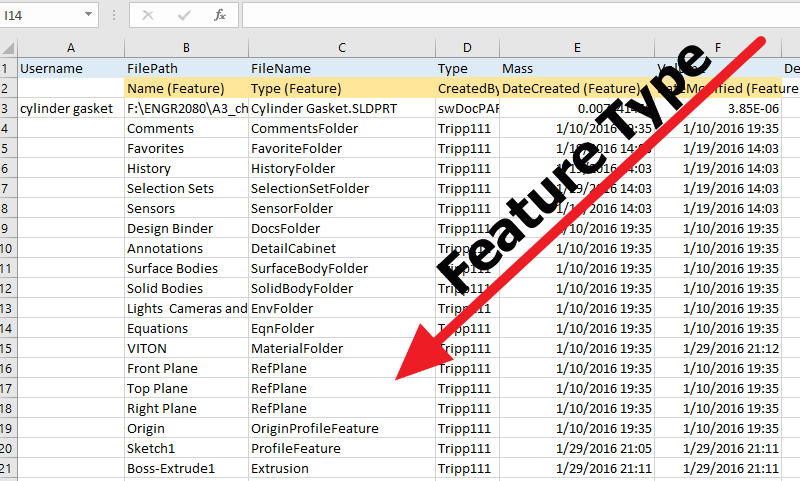

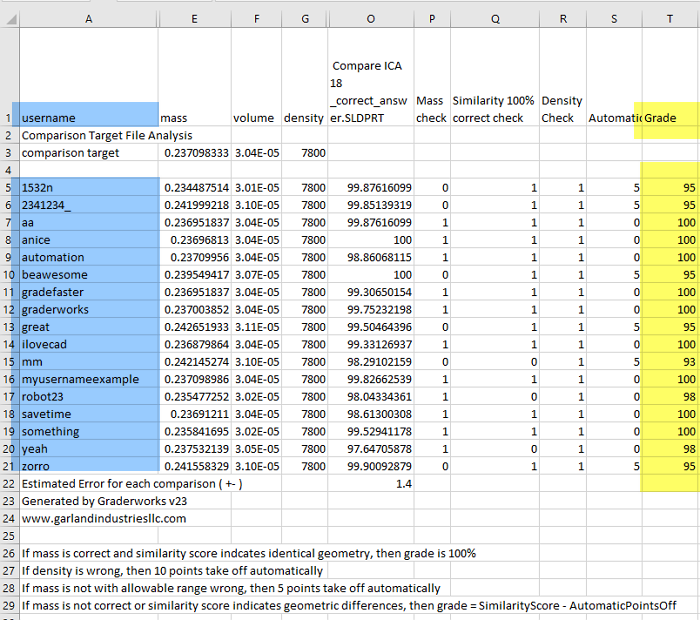

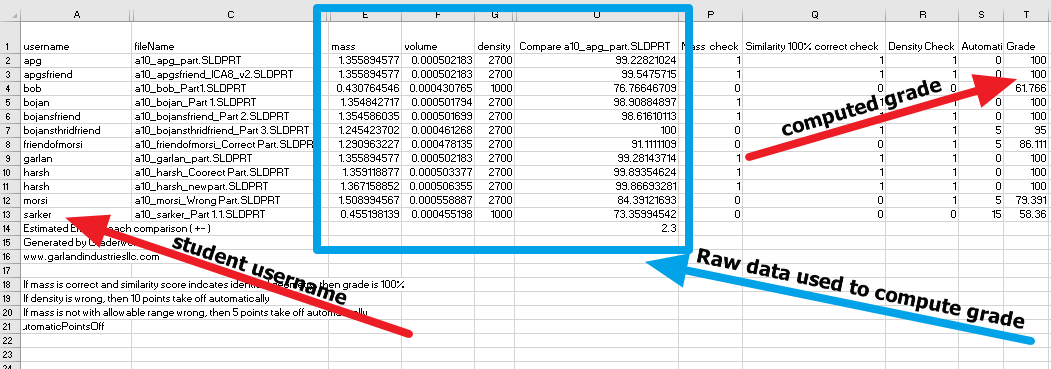

- Grade student's SOLIDWORKS files quickly

- Catch Plagiarism

- Export SOLIDWORKS files to another format in bulk

Recent Articles

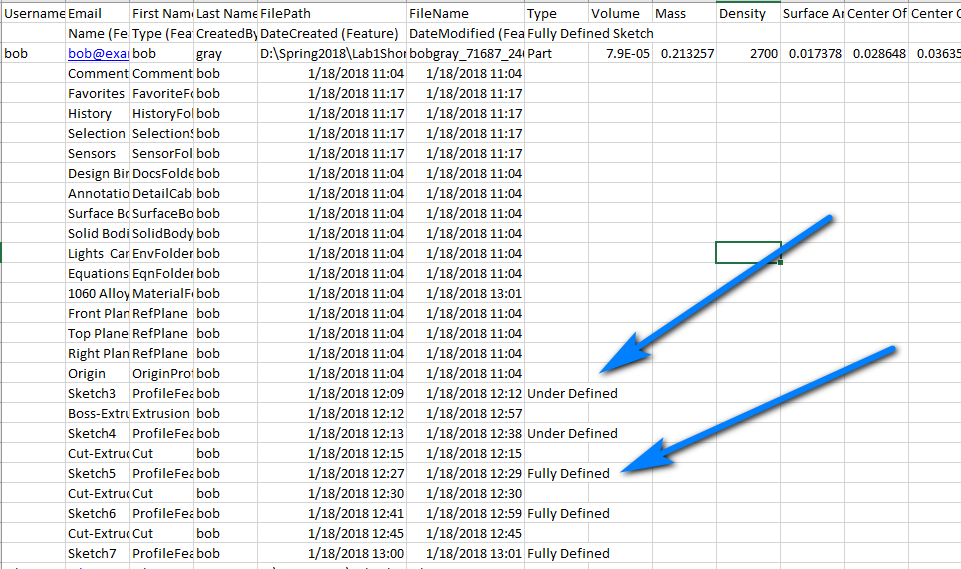

Evaluation of Humans and Software for Grading in an Engineering 3D CAD Course

Anthony Garland and Sarah Grigg published a paper showing the effectiveness of a

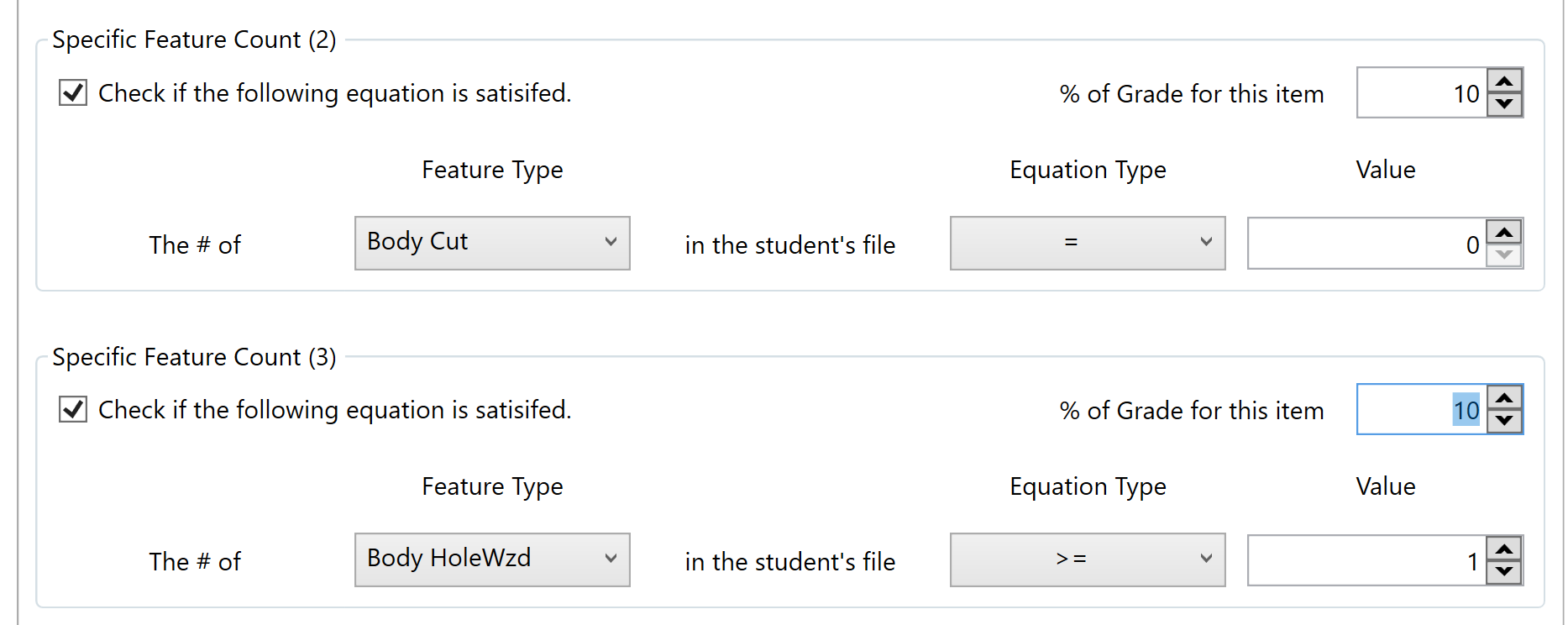

New Grading Items in GW 4.07 - 4.30

Gradeworks can help you automated SOLIDWORKS grading. New grading items include:

Graderworks 3.10 Check for Fully Defined Sketches

What's new in Graderworks 3.10? Increased data collection speed. Check for fully

Graderworks: SW 2017, Config files, Command line args

Graderworks 2.36 and higher is compatible with SOLIDWORKS 2017. Graderworks now

Graderworks: An Official SOLIDWORKS Solution Partner

Garland Industries is happy to announce that Graderworks is now an official SOL

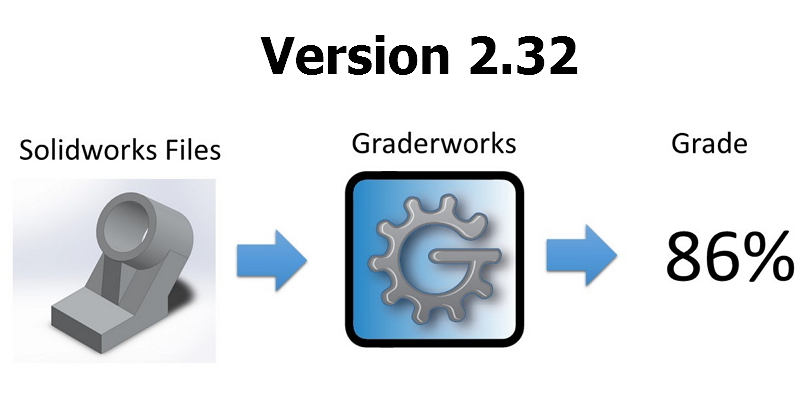

Graderworks 2.32 Release

Graderworks 2.32 represents continued incremental improvement in the overall qua

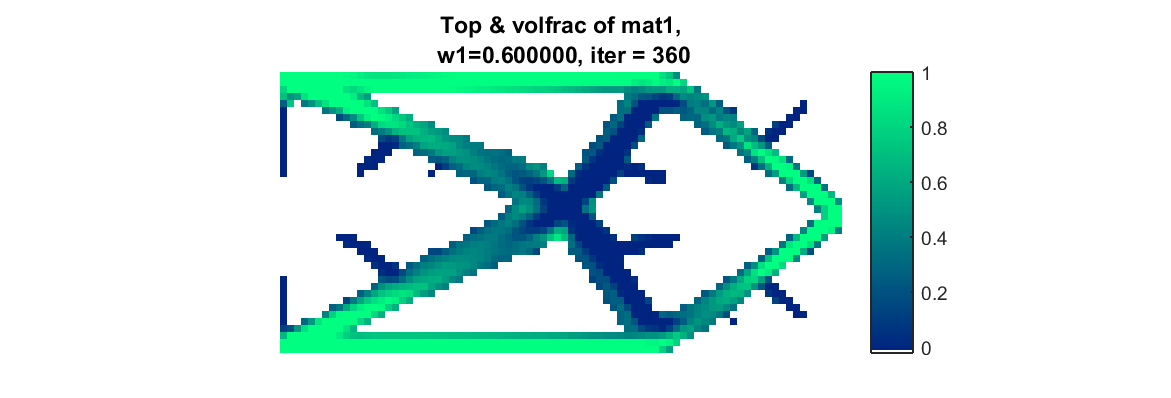

Design Automation Example

A design automation example is given showing topology optimization coupled with

Graderworks 2.3 Release

Graderworks 2.3 allows you to compare the geometric similarity of .stl files wit

Turnitin vs. Graderworks

Graderworks is the Turnitin of 3D models. Not using a plagiarism checker in a So

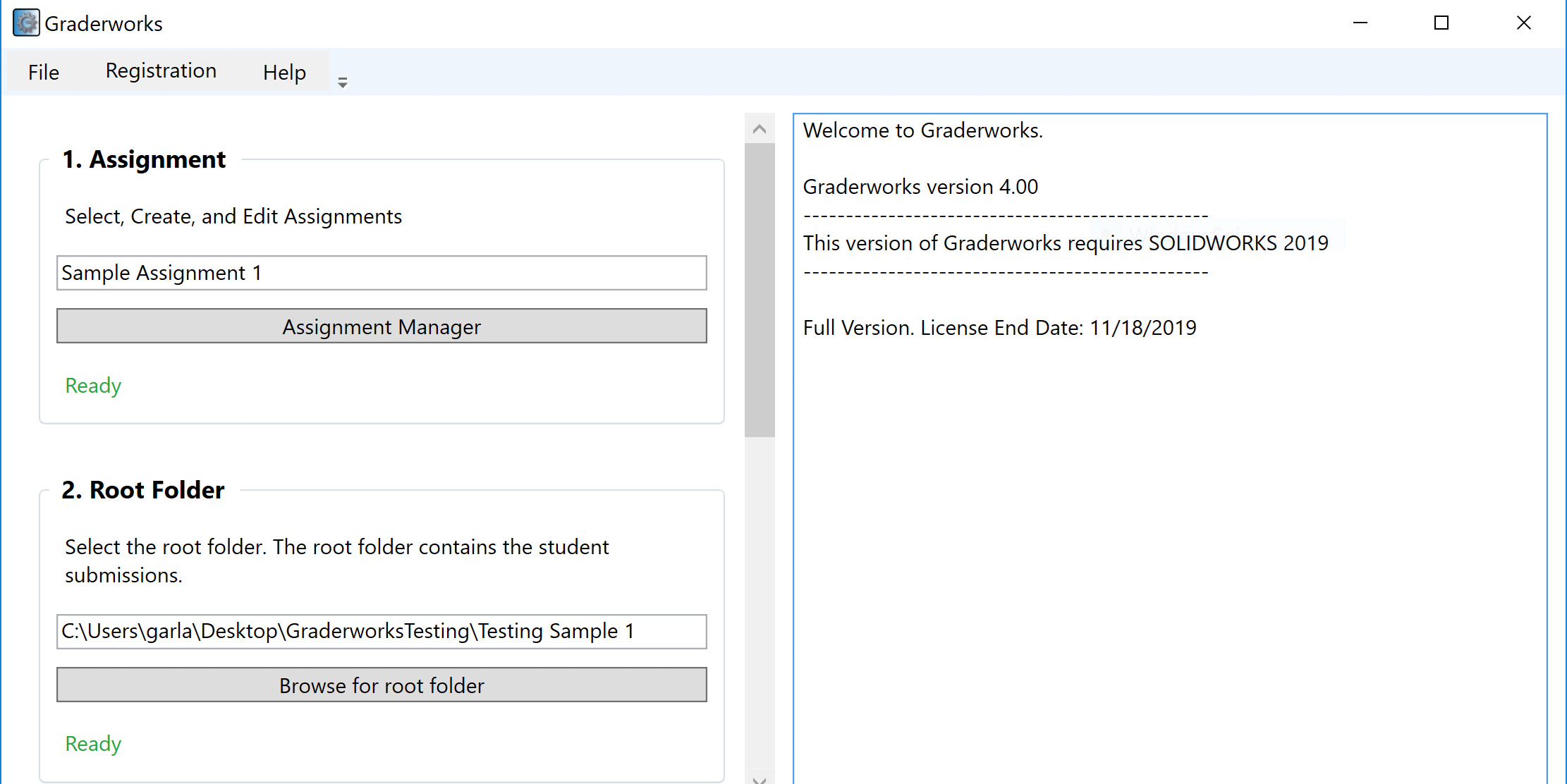

Getting Started with Graderworks

This tutorial shows how to get started analyzing and grading Solidworks part fil

The Making of Graderworks Video

As an engineering entrepreneur, marketing is not my strength. To make high-quali

Organizing hundreds of .stl files for 3D printing

How would you 3D print hundreds of .stl files in the shortest time possible usin

What is unique about 3D printing?

3D Printing offers many new exciting possibilities, but why is it unique? Three

How 3D printing works

3D Printing requires three steps. 1. Getting a 3D model. 2. Slicing the model to

Preprocessing files for Graderworks: Converting .rar to .zip

Solidworks students submit .rar files instead of .zip. Graderworks requires .zip

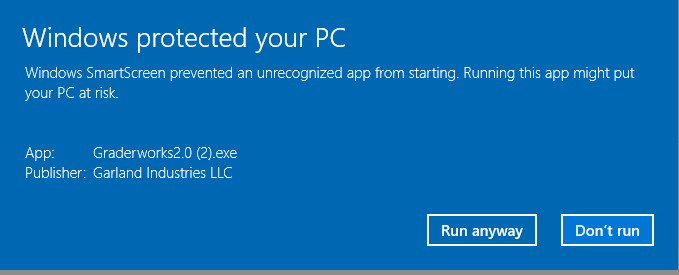

Windows Smart Screen and Code Signing

A short tutorial on how to sign a Windows installer and what the smart screen fi

What should we 3D print?

3D Printing opens the possibility of mass customization of consumer products. Ma

Software, dying on the journey from academic project to commercial tool.

Does software make it from academic research to useful commercial tools? Ignoran