404

Join our free mailing list!

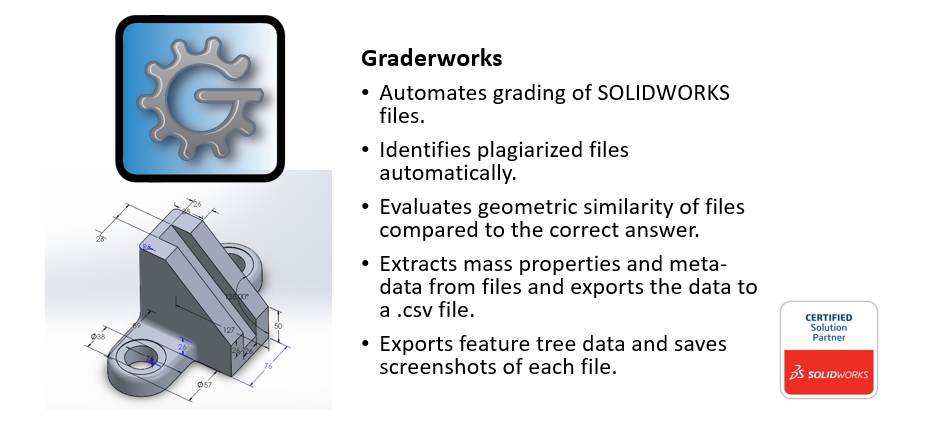

Graderworks

- Grade student's SOLIDWORKS files quickly

- Catch Plagiarism

- Export SOLIDWORKS files to another format in bulk

Recent Articles

Evaluation of Humans and Software for Grading in an Engineering 3D CAD Course

Anthony Garland and Sarah Grigg published a paper showing the effectiveness of a

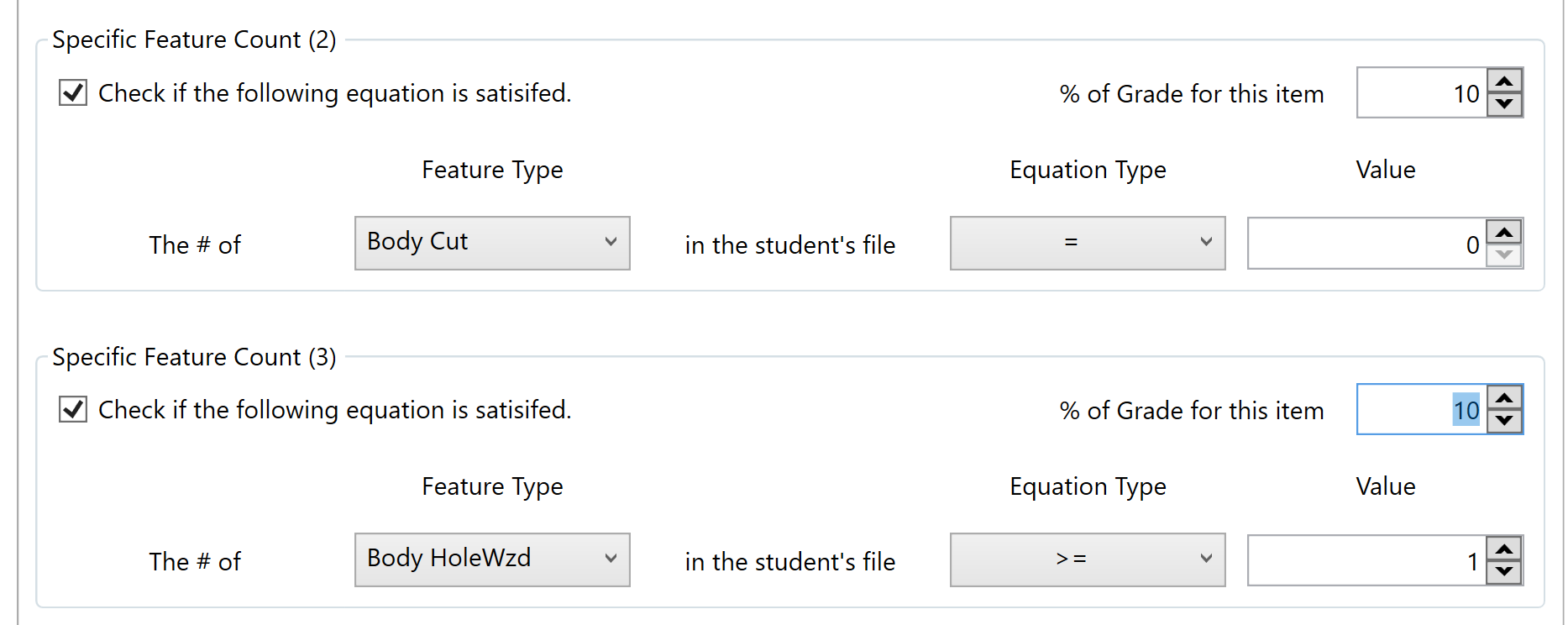

New Grading Items in GW 4.07 - 4.30

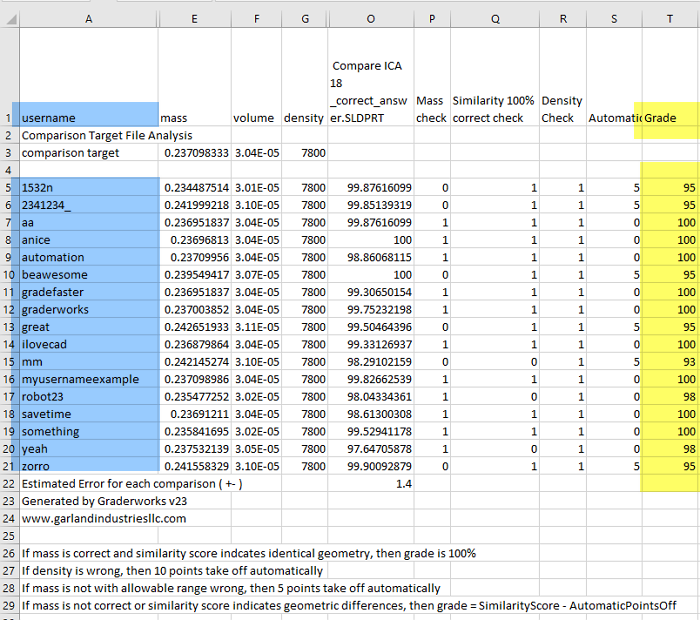

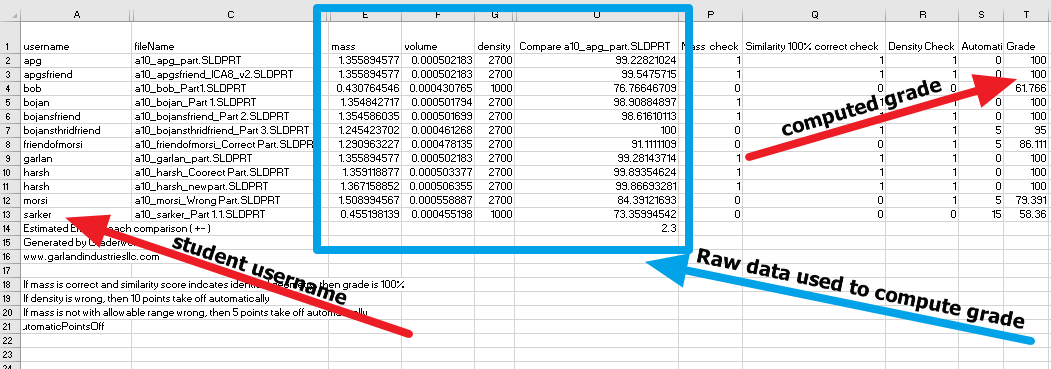

Gradeworks can help you automated SOLIDWORKS grading. New grading items include:

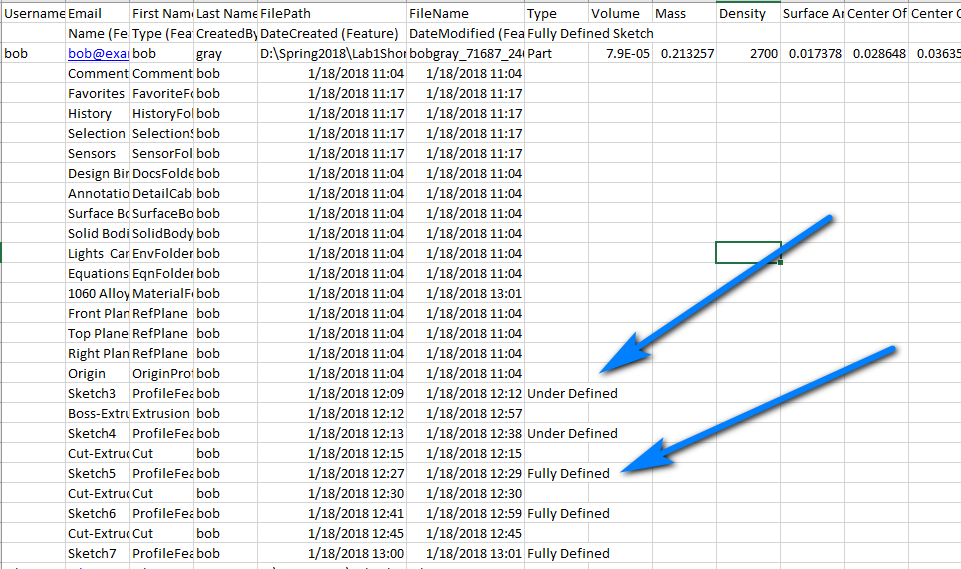

Graderworks 3.10 Check for Fully Defined Sketches

What's new in Graderworks 3.10? Increased data collection speed. Check for fully

Graderworks: SW 2017, Config files, Command line args

Graderworks 2.36 and higher is compatible with SOLIDWORKS 2017. Graderworks now

Graderworks: An Official SOLIDWORKS Solution Partner

Garland Industries is happy to announce that Graderworks is now an official SOL

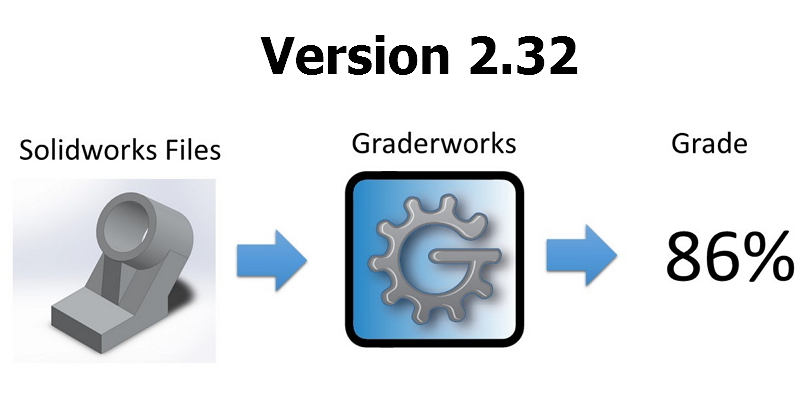

Graderworks 2.32 Release

Graderworks 2.32 represents continued incremental improvement in the overall qua

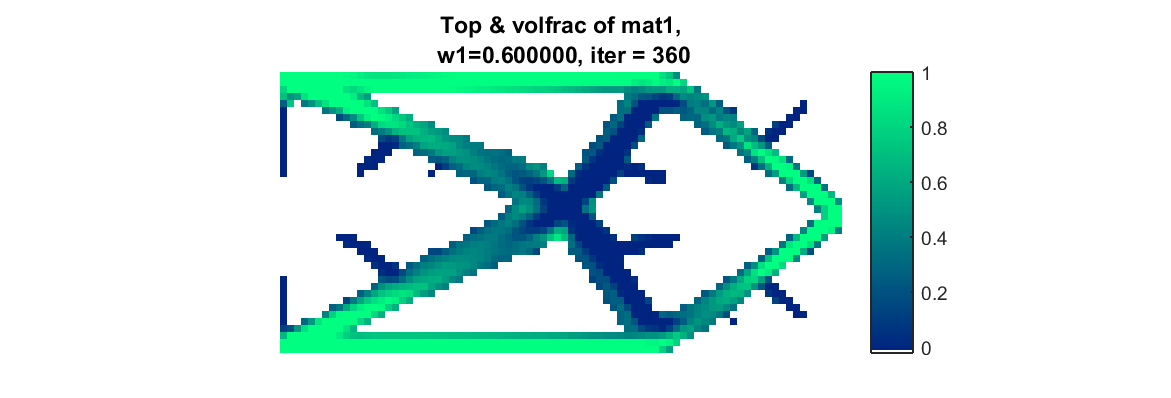

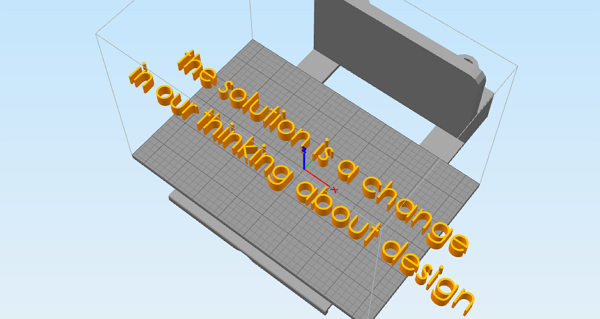

Design Automation Example

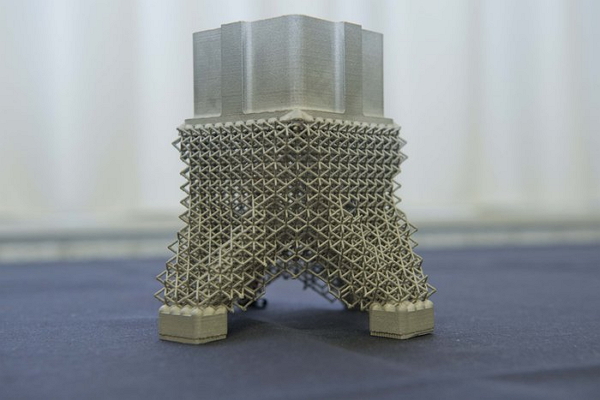

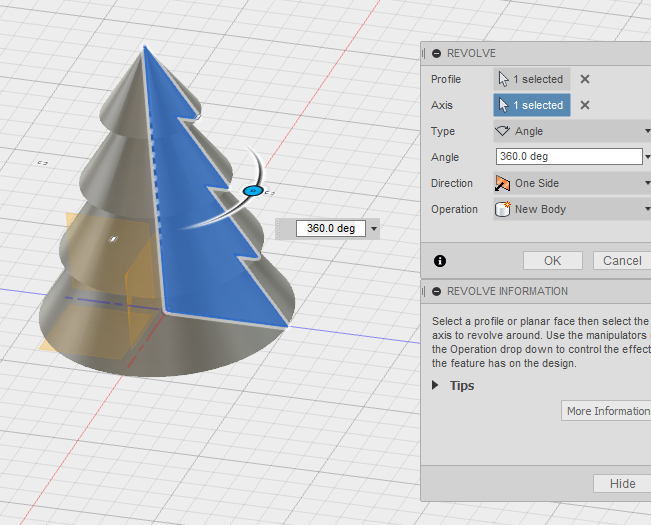

A design automation example is given showing topology optimization coupled with

Graderworks 2.3 Release

Graderworks 2.3 allows you to compare the geometric similarity of .stl files wit

Turnitin vs. Graderworks

Graderworks is the Turnitin of 3D models. Not using a plagiarism checker in a So

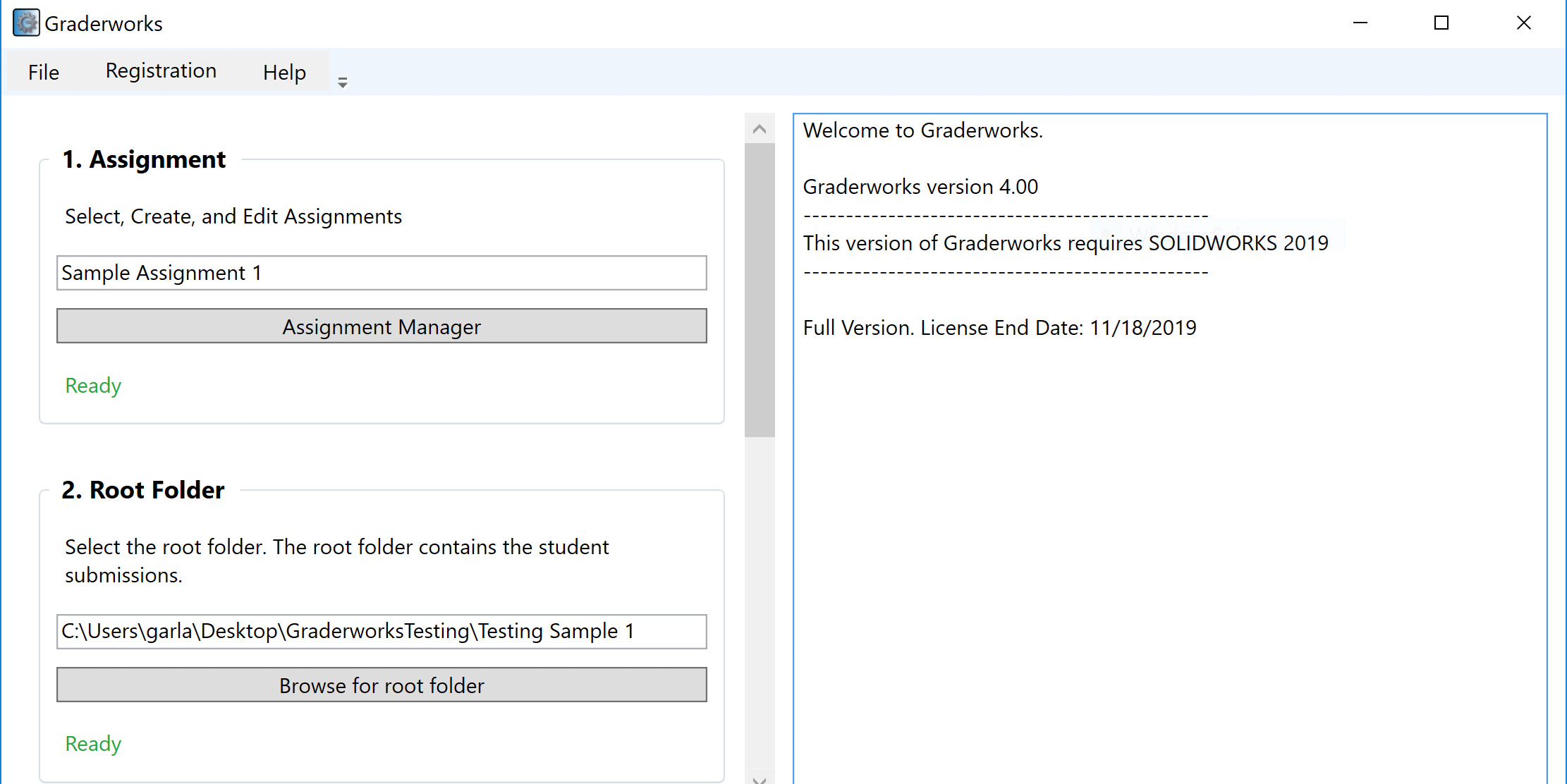

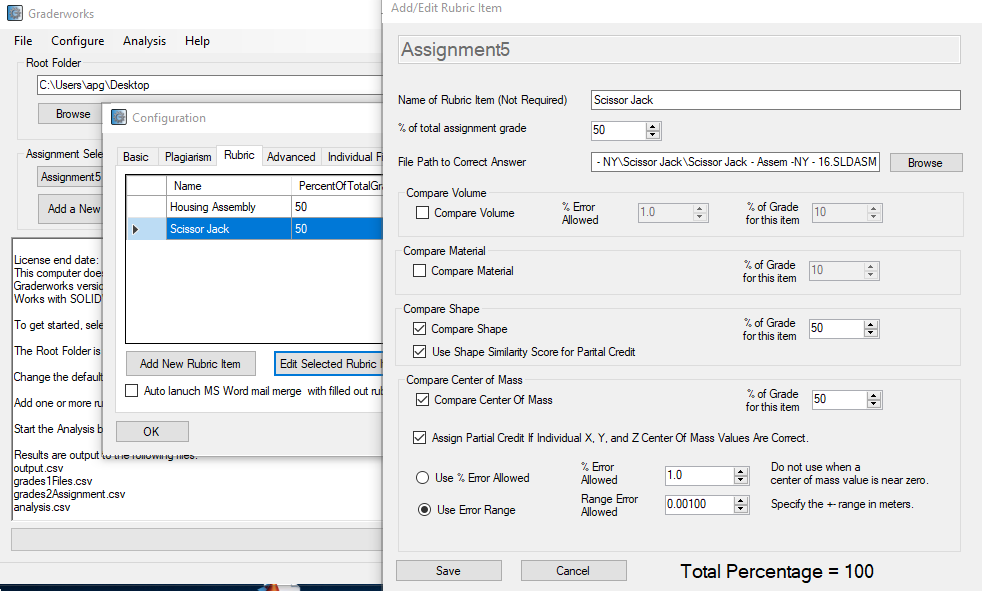

Getting Started with Graderworks

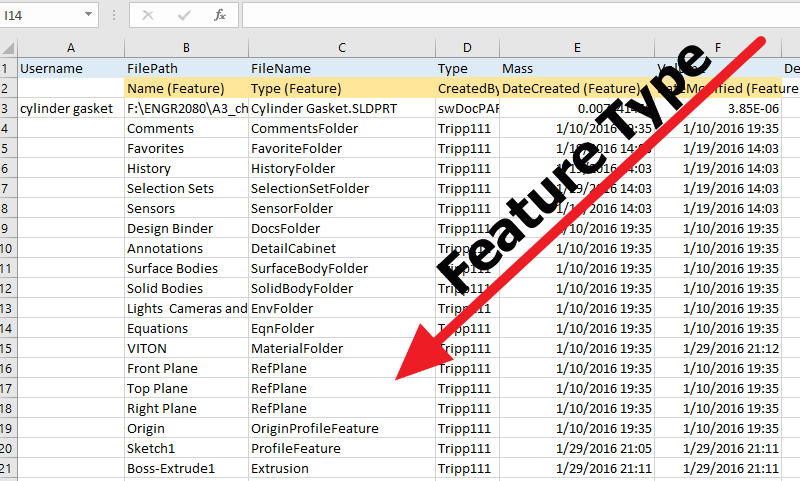

This tutorial shows how to get started analyzing and grading Solidworks part fil

The Making of Graderworks Video

As an engineering entrepreneur, marketing is not my strength. To make high-quali

Organizing hundreds of .stl files for 3D printing

How would you 3D print hundreds of .stl files in the shortest time possible usin

What is unique about 3D printing?

3D Printing offers many new exciting possibilities, but why is it unique? Three

How 3D printing works

3D Printing requires three steps. 1. Getting a 3D model. 2. Slicing the model to

Preprocessing files for Graderworks: Converting .rar to .zip

Solidworks students submit .rar files instead of .zip. Graderworks requires .zip

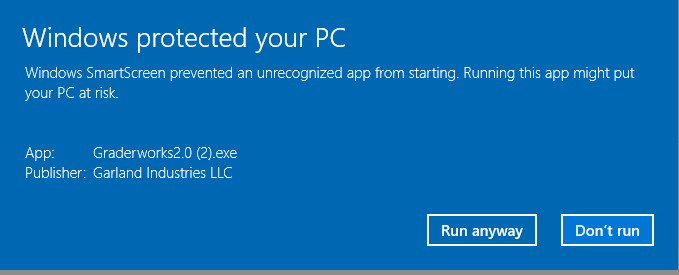

Windows Smart Screen and Code Signing

A short tutorial on how to sign a Windows installer and what the smart screen fi

What should we 3D print?

3D Printing opens the possibility of mass customization of consumer products. Ma

Software, dying on the journey from academic project to commercial tool.

Does software make it from academic research to useful commercial tools? Ignoran